EN ISO 11612: Comprehensive Guide for Heat Protective Clothing

EN ISO 11612 is a widely recognized standard that defines the performance requirements for heat-protective clothing. Used mostly across Europe, Asia, and Africa, EN 11612's performance requirements are designed to protect workers from thermal hazards including flames, radiant heat, convective heat, contact heat, and molten metal splashes. Understanding this certification system ensures that the protective clothing assigned is effective, legal, and appropiate for specific workplace hazards.

Important Note on Liability and Standards Compliance

This article is provided for informational purposes only. Standards and regulations are subject to change. Always verify the current edition and requirements directly with regulatory bodies such as the International Organization for Standardization (ISO) , the European Committee for Standardization (CEN) , or your local occupational safety authority. Employers are responsible for conducting their own hazard assessments and ensuring compliance with applicable laws and standards in their jurisdiction.

Table of Contents

- What is EN ISO 11612?

- What Does EN ISO 11612 Protect Against?

- The EN ISO 11612 Letter Coding System: A–F

- How to Read an EN ISO 11612 Label

- Types of Products Covered by EN ISO 11612

- Areas of Applications for EN ISO 11612

- Geographic Adaptation of EN ISO 11612

- Standards Updates and Versions

What is EN ISO 11612?

EN ISO 11612 is a European standard that specifies minimum performance requirements for protective clothing used against heat and flame. Unlike application-specific standards, it focuses on fabric performance and how the materials should behave when exposed to different thermal hazards, making it applicable across multiple industries.

The standard is officially titled “Protective clothing, Protection against heat and flame, Minimum performance requirements" and is maintained by the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN). It uses a letter coding system from A to F, which appears directly on garment labels to indicate the specific types of heat and flame protection provided, allowing safety managers and workers to quickly identify suitable protection.

What Does EN ISO 11612 Protect Against?

EN ISO 11612 protects the wearer against limited flame spread properties, radiant, convective, and/or contact heat, as well as molten metal sprays or splashes in high-temperature industrial environments.

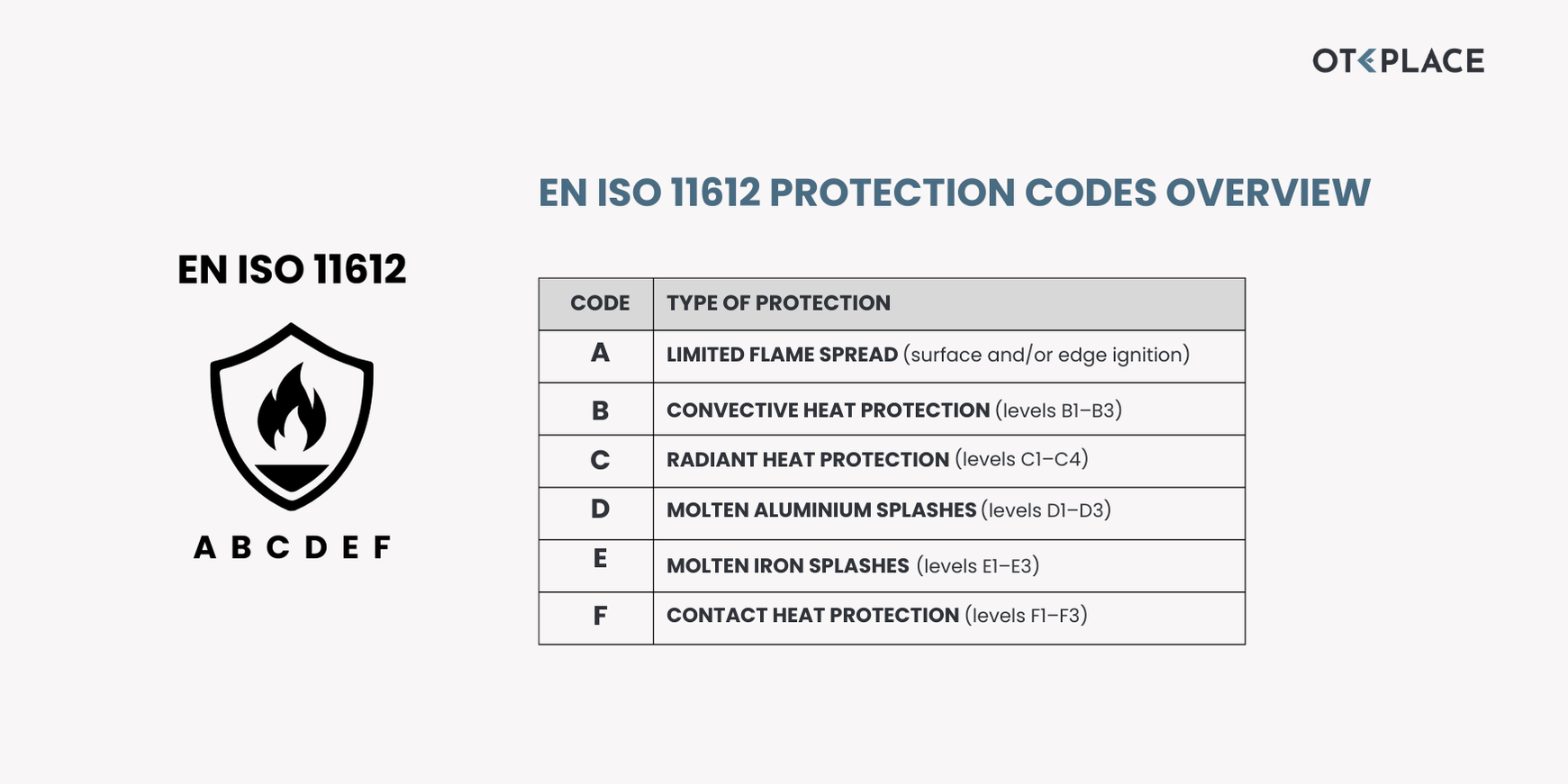

The EN ISO 11612 Letter Coding System: A–F

EN ISO 11612 uses a letter coding system from A to F to show different types of heat protection. Each letter represents a specific hazard and protective capability.

Code A: Limited Flame Spread

Code A tests test for limited flame spread, meaning how well a fabric resists ignition and spreading flames when exposed to fire. It includes two test methods:

A1: Surface Ignition

Tests what happens when a flame is applied directly to the surface the material.

The fabric must not ignite and must self-extinguish quickly after a ten-second flame exposure. It is then evaluated for charring and burn-through.

A2: Edge Ignition

Tests flame exposure along the edge of the material.

This ensures flames do not spread through seams or edges. A flame is applied to the edge for ten seconds and the fabric's behaviour is evaluated.

Key Point: All certified EN ISO 11612 clothing must pass at least A1 or both A1 and A2. Code A is mandatory for all garments; without it a garment caannot be certified to EN ISO 11612.

Code B: Convective Heat Protection

Code B measures protection against convective heat from flames, hot air, and gases that move through air currents. Performance levels are measured using the Heat Transmission Index (HTI), which records how long it takes for heat to reach a critical temperature (44°C/111°F) where skin burns can occur. Higher values mean longer protection time.

The performance levels are:

| Code | Time to Hole Formation |

|---|---|

| B1 | 4 to < 10 seconds |

| B2 | 10 to < 20 seconds |

| B3 | 20+ seconds |

Key Point: Convective heat is a major risk in flash fire, welding, and high-temperature industrial environments.

Code C: Radiant Heat Protection

Code C measures protection against radiant heat like infrared rays, which travels directly from a heat source without air movement. Performance levels are measured using the Radiant Heat Index (RHTI), following a method similar to Code B.

The four levels range from lowest to highest protection:

| Code | Time to Hole Formation |

|---|---|

| C1 | 7 to < 20 seconds |

| C2 | 20 to < 50 seconds |

| C3 | 50 to < 95 seconds |

| C4 | Minimum 95 seconds |

Key Point: Radiant heat protection is critical in foundries, welding operations, and industrial settings with exposed hot machinery.

Code D: Molten Metal Aluminum Splashes

Code D tests protection against splashes of molten aluminum. The test evaluates how much molten metal the fabric can withstand before damage occurs. During testing, molten aluminum at 780°C (1436°F) is poured onto the fabric, with a membrane underneath to simulate human skin.

To pass, the membrane must remain intact after the test.

| Code | Molten Metal Quantity |

|---|---|

| D1 | 100 g to < 200 g |

| D2 | 200 g to < 350 g |

| D3 | Minimum 350 g |

Key Point: Molten aluminium protection is commonly needed in automotive, aerospace, and general manufacturing industries.

Code E: Molten Cast Iron

Code E measures protection against splashes of molten iron, using a test method similar to Code D. A film of PVC is placed beneath the fabric to simulate human skin.

Molten iron at 1400°C/2552°F (±20°C) is poured onto the material. The garment passes if the underlying membrane remains intact.

| Code | Molten Cast Iron Quantity |

|---|---|

| E1 | 60 to 120 g |

| E2 | 120 to 200 g |

| E3 | Over 200 g |

Key Point: Iron and steel foundries and heavy metal processing environments rely heavily on Code E protection.

Code F: Contact Heat

Code F measures protection against contact heat when a garment touches hot objects, heated surfaces, or equipment.

| Code | Contact Heat Protection Time |

|---|---|

| F1 | 5 to 10 seconds |

| F2 | 10 to 15 seconds |

| F3 | Over 15 seconds |

Key Point: Contact heat exposures occurs frequently in metalworking, welding, and manufacturing environments.

How to Read an EN ISO 11612 Label

Every EN ISO 11612–certified garment must pass Code A and at least one additional protection code. Within each code, higher numbers indicate higher protection levels.

A typical label may look like:

EN ISO 11612: A1, B1, C3, D3, E3, F0

This means the garment provides the following protection:

- A1: Surface flame ignition

- B1: Convective heat protection for 4-10 seconds

- C3: Radiant heat protection for 50-95 seconds

- D3: Resistance to molten aluminium splash for a minimum of 350 grams

- E3: Resistance to molten cast iron for over 200 grams

- F0: No resistance to contact heat

These specific codes appear on the garment label to show what hazards the clothing is designed to protect against.

Understanding this code system makes it easier to select the right clothing for specific workplace risks.

UNSURE WHICH EN ISO 11612 CERTIFIED PRODUCT YOU NEED?

If you’re unsure which level of protection is required for your industry or application, our team can help you identify suitable options based on your specific risks and requirements. Contact us for further guidance.

Products Covered by EN ISO 11612

EN ISO 11612 standard applies to a wide range of heat-and-flame protective garments. Knowing which products fall under this standards helps identify appropriate PPE for the right working environment.

Garments That Can Be Certified to EN ISO 11612

- Shirts & jackets

- Pants & trousers

- Overalls & coveralls

- Aprons

- Waistcoats & vests

- Hood & head protection

Garments Not Certified to EN ISO 11612

Many manufacturers recommend wearing EN ISO 11612 certified garments as part of a complete protective ensemble that includes gloves certified to EN 407, footwear certified to EN ISO 20345, and headgear certified to EN 397. The overall protection level is determined by the weakest component in the PPE ensemble. Each item must be suitable for the specific hazard to ensure effective protection.

Areas of Applications for EN ISO 11612

EN ISO 11612 protective clothing is used across multiple industries where workers are exposed to thermal hazards such as heat, flames, and/or molten materials. Including::- Welding & metal fabrication

- Foundries & metal casting

- Steel Mills & iron works

- Chemical Processing & petrochemicals

- Glass & ceramics manufacturing

- Aerospace & automotive manufacturing

Geographic Adaptation of EN ISO 11612

EN ISO 11612 is the mandatory standard across the European Union, governed by EU Directive 89/686/EEC on personal protective equipment. It is widely recognized and adopted in Asia, Australia, Canada, and many other regions as the primary heat protection standard.

European Union: EN ISO 11612 is mandatory for all heat-protective garments sold within the EU member states. The Notified Body system ensures third-party certification and ongoing market surveillance.

United Kingdom: Following Brexit, the UK adopted EN ISO 11612 into British Standards (BS EN ISO 11612) and maintains equivalence with EU requirements through the UKCA (UK Conformity Assessed) marking system.

Asia-Pacific Region: Countries including Australia, New Zealand, and Singapore recognize EN ISO 11612 as the primary standard. Japan and South Korea have adopted similar standards with strong alignment to EN ISO 11612 requirements.

North America: In the United States and Canada, EN ISO 11612 coexists with NFPA standards (NFPA 2112 for flash fire protection). Many manufacturers design garments to meet both standards simultaneously to serve multinational companies and export markets. Canada’s CSA (Canadian Standards Association) recognizes EN ISO 11612 compliance.

Middle East and Africa: EN ISO 11612 is increasingly adopted, particularly in oil and gas operations where European regulatory influence is strong.

Important Consideration: Always verify which standards apply in your specific jurisdiction, as regional requirements can vary. Some countries or industries may require both EN ISO 11612 and additional certifications.

Standards Updates and Versions

EN ISO 11612 is periodically revised to reflect new testing methods and fabric innovations. Always verify which edition a garment meets, as older versions may have different requirements or test parameters than current versions.

Official Sources for Current Information

For the most current information on EN ISO 11612 requirements, editions, and amendments, consult:

- The International Organization for Standardization (ISO): www.iso.org

- The European Committee for Standardization (CEN): www.cen.eu

- Notified Bodies and Competent Authorities in your jurisdiction

Employers and safety professionals should regularly review official standard documentation and regulatory guidance to ensure ongoing compliance and worker safety.

Need Further Guidance on Selecting EN ISO 11612 Protective Clothing?

For further clarification or case-specific questions, contact our team for guidance based on your application and exposure risks.